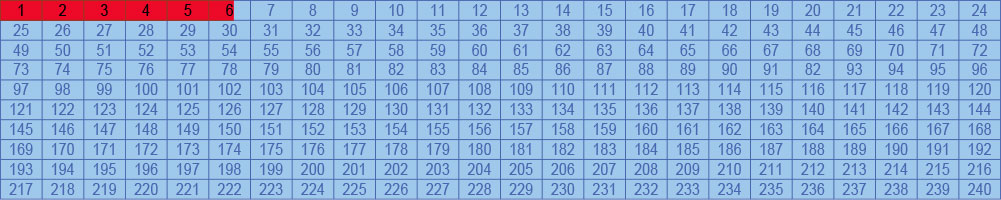

Heat Recovery System Payback vs. Fuel Savings

Savings analysis of Cain Industries’ exhaust heat recovery equipment showing: initial cost, BTU recovered, payback period, return on investment, annual and life expectancy savings.

Exhaust Steam Generator - ESG1

Gas & Diesel Cogeneration Market| DATA without a Cain System | PERFORMANCE with a Cain System | |||

| Engine Generator | ESG1 | |||

| Heat Sink | Steam Demand | Operating Steam Pressure | 10 PSI | |

| Waste Exhaust Temp. | 1,150°F | Final Exhaust Temp. | 301°F | |

| Water Temp. Inlet | N/A | Boiler Horsepower | 51 BHP | |

| SCFM | 1,598 | Equivalent Evaporation | 1,743 lb/hr | |

| Fuel Type | Natural Gas | Exhaust Pressure Drop | 1.44" WC | |

| O2 Content | N/A | BTU/hr Recovered | 1,691,000 | |

| Excess Air | N/A | Total Cost | $70,674 | |

| Fuel Cost Per Therm | $0.60 | |||

| Annual Operating Hours | 8,700 | Payback: | 9.6 mo. | |

| Annual ROI: | 125% | |||

| Annual Savings: | $88,277 | |||

| Life Expectancy Savings: $1,765,540 (20 years) | ||||

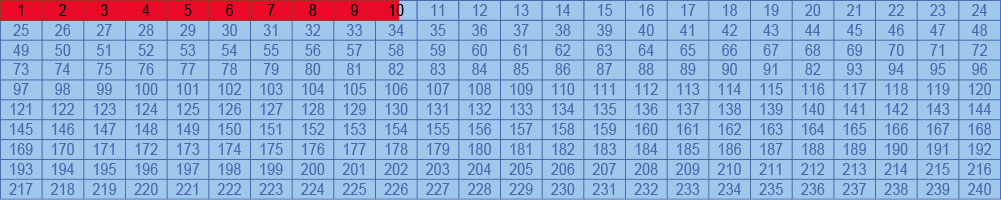

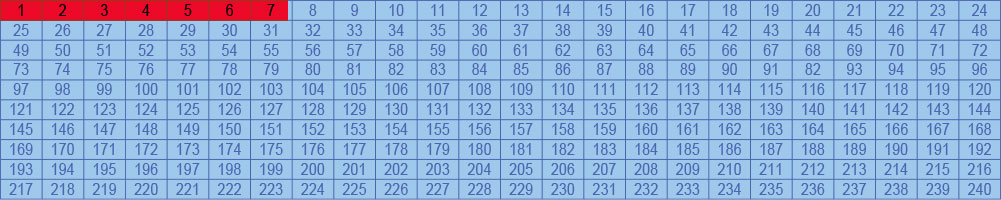

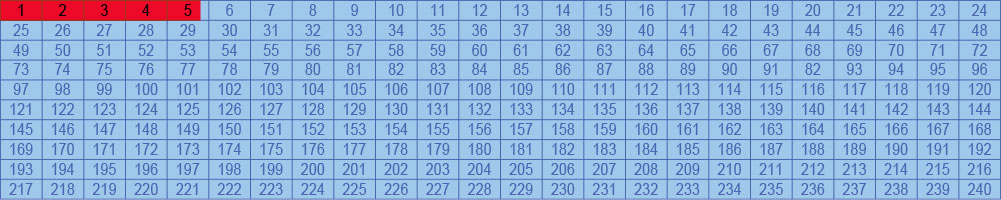

Each cell represents one month of operation over equipment lifetime (240 months = 20 years).

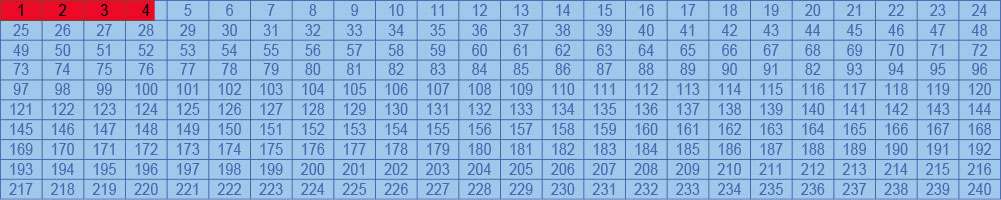

Heat Recovery Silencer Radial - HRSR x7

Gas & Diesel Cogeneration Market| DATA without a Cain System | PERFORMANCE with a Cain System | |||

| Engine Generator | HRSR | |||

| Heat Sink | Glycol/Water Loop | Circulating Liquid Flow | 300 GPM | |

| Waste Exhaust Temp. | 922°F | Final Exhaust Temp. | 387°F | |

| Water Temp. Inlet | 180°F | Water Temp. Outlet | 194.1°F | |

| SCFM | 2,766 | Water Pressure Drop | 0.49 PSIG | |

| Fuel Type | Landfill Gas | Exhaust Pressure Drop | 0.73" WC | |

| O2 Content | N/A | BTU/hr Recovered | 1,845,000 | |

| Excess Air | N/A | Total Cost | $47,431 | |

| Fuel Cost Per Therm | $0.60 | |||

| Annual Operating Hours | 6,000 | Payback: | 6.9 mo. | |

| Annual ROI: | 175% | |||

| Annual Savings: | $83,006 | |||

| Life Expectancy Savings: $1,660,120 (20 years) | ||||

Each cell represents one month of operation over equipment lifetime (240 months = 20 years).

U-Tube Recovery - UTR1

Gas & Diesel Cogeneration Market| DATA without a Cain System | PERFORMANCE with a Cain System | |||

| Engine Generator | UTR1 | |||

| Heat Sink | Glycol/Water Loop | Circulating Liquid Flow | 400 GPM | |

| Waste Exhaust Temp. | 645°F | Final Exhaust Temp. | 357°F | |

| Water Temp. Inlet | 250°F | Water Temp. Outlet | 263.3°F | |

| SCFM | 6,739 | Water Pressure Drop | 0.04 PSIG | |

| Fuel Type | Natural Gas | Exhaust Pressure Drop | 2.00" WC | |

| O2 Content | N/A | BTU/hr Recovered | 2,341,000 | |

| Excess Air | N/A | Total Cost | $22,455 | |

| Fuel Cost Per Therm | $0.60 | |||

| Annual Operating Hours | 6,000 | Payback: | 4.8 mo. | |

| Annual ROI: | 250% | |||

| Annual Savings: | $56,176 | |||

| Life Expectancy Savings: $1,123,520 (20 years) | ||||

Each cell represents one month of operation over equipment lifetime (240 months = 20 years).

Rectangular Tube Recovery - RTR

Boiler Economizer Market| DATA without a Cain System | PERFORMANCE with a Cain System | |||

| 55,000 PPH Steam Boiler | RTR | |||

| Heat Sink | Boiler Feedwater | Boiler Feedwater Flow | 118 GPM | |

| Waste Exhaust Temp. | 509°F | Final Exhaust Temp. | 343°F | |

| Water Temp. Inlet | 227°F | Water Temp. Outlet | 276°F | |

| BTU/hr Burner Input | 70,000 MBTU | Water Pressure Drop | 0.87 PSIG | |

| Fuel Type | Kerosene | Exhaust Pressure Drop | 0.68" WC | |

| O2 Content | 2.95% | BTU/hr Recovered | 2,781,000 | |

| Excess Air | 15% | Total Cost | $45,009 | |

| Fuel Cost Per Therm | $0.70 | |||

| Annual Operating Hours | 4,000 | Payback: | 5.6 mo. | |

| Annual ROI: | 215% | |||

| Annual Savings: | $96,816 | |||

| Life Expectancy Savings: $1,936,320 (20 years) | ||||

Each cell represents one month of operation over equipment lifetime (240 months = 20 years).

Fin Coil Recovery - FCR

Boiler Economizer Market| DATA without a Cain System | PERFORMANCE with a Cain System | |||

| 500 HP Steam Boiler | FCR | |||

| Heat Sink | Process Water | Boiler Feedwater Flow | 25 GPM | |

| Waste Exhaust Temp. | 400°F | Final Exhaust Temp. | 268°F | |

| Water Temp. Inlet | 120°F | Water Temp. Outlet | 168.6°F | |

| BTU/hr Burner Input | 20,922 MBTU | Water Pressure Drop | 6.6 PSIG | |

| Fuel Type | Natural Gas | Exhaust Pressure Drop | 0.47" WC | |

| O2 Content | 3% | BTU/hr Recovered | 608,396 | |

| Excess Air | 18% | Total Cost | $6,717 | |

| Fuel Cost Per Therm | $0.60 | |||

| Annual Operating Hours | 6,000 | Payback: | 3.7 mo. | |

| Annual ROI: | 326% | |||

| Annual Savings: | $21,902 | |||

| Life Expectancy Savings: $438,040 (20 years) | ||||

Each cell represents one month of operation over equipment lifetime (240 months = 20 years).